Product

At present, the plastic pipe industry mainly consists of polyvinyl chloride (PVC-U) pipes, polyethylene (PE)

pipes and polypropylene (PP-R) pipes. Among them, polyethylene (PE) pipes are widely used in building

water supply, building drainage, buried drainage pipes, building heating, gas pipelines, electrical and

telecommunications protection casings, industrial pipes, agricultural pipes, etc. due to their unique advantages.

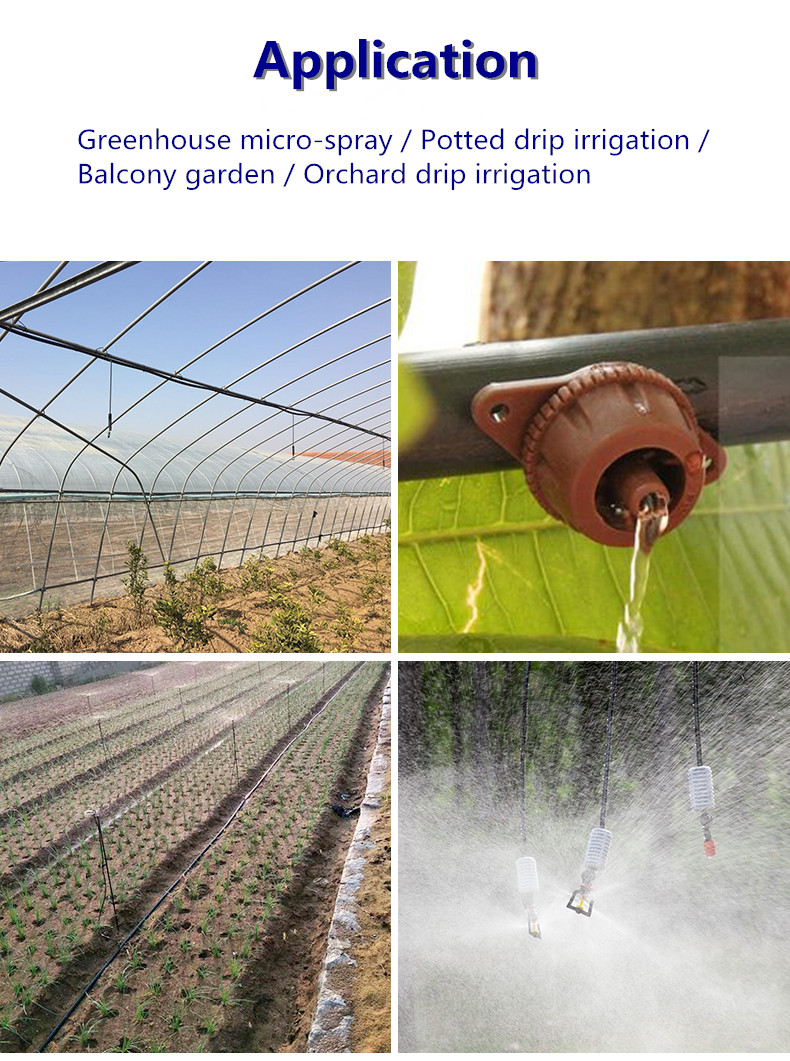

It is mainly used in urban water supply, city gas supply and farmland irrigation.

1) Polyethylene (PE) pipe for water supply;

2) Buried polyethylene pipe for gas;

3) PE biogas pipe;

4) High density polyethylene (HDPE) silicon core tube;

5) HDPE double wall corrugated plastic pipe;

6) PE buried cable protection Casing;

7) PE porous line sheathed tube;

8) Polypropylene (PP-R) tube for hot and cold water (ppr tube)

9) PE Telecom sheath tube

High density polyethylene, the English name is “High Density Polyethylene”, referred to as “HDPE”. HDPE is a highly crystalline, non-polar thermoplastic resin. The original HDPE has a milky white appearance and a semi-transparent shape in a thin section. PE has excellent resistance to most of the characteristics of living and industrial chemicals. Certain types of chemicals can cause chemical corrosion, such as corrosive oxidants (concentrated nitric acid), aromatic hydrocarbons (xylene), and halogenated hydrocarbons (carbon tetrachloride). The polymer is non-hygroscopic and has good water vapor resistance and can be used for packaging purposes. HDPE has excellent electrical properties, especially high dielectric strength, making it suitable for wire and cable. Medium to high molecular weight grades have excellent impact resistance, both at ambient temperatures and even at low temperatures of -40F. HDPE is a thermoplastic polyolefin formed by copolymerization of ethylene. Although HDPE was introduced in 1956, the plastic has not yet reached maturity. This versatile material is constantly developing its new uses and markets.

In all engineering plastics, the wear resistance of HDPE is the crown of plastic, which is the most eye-catching. The higher the molecular weight, the more wearable the material is, even more than many metallic materials (such as carbon steel, stainless steel, bronze, etc.). The service life under strong corrosion and high wear conditions is 4-6 times that of steel pipes, 9 times that of ordinary polyethylene; and the conveying efficiency is increased by 20%. It has good flame retardant and antistatic properties and meets the standard requirements. The service life of the well is more than 20 years, the economic benefit is remarkable, the impact resistance, wear resistance and double resistance are remarkable.

PE plastic pipe for sewage disposal is also called high-density polyethylene pipe, English: HDPE. This type of pipe is often used as the preferred pipe for municipal engineering and is mainly used in the sewage treatment industry. Because of its characteristics of wear resistance, acid and corrosion resistance, high temperature resistance and high pressure resistance, it has gradually replaced the traditional pipe materials such as steel pipes and cement pipes in the market, especially because the pipe is light in weight, easy to install and move, and is a new material. The first choice. Users should pay special attention to the following points when selecting pipes of this material:

1. Special attention should be paid to the selection of raw materials for plastic pipes. There are thousands of grades of polyethylene raw materials, and there are as many as a few thousand yuan per ton of raw materials on the market. The products produced from such raw materials cannot be constructed, otherwise the rework loss will be huge.

2. The choice of pipeline manufacturers should be based on formal professional manufacturers.

3. When choosing to purchase PE plastic pipe, you should inspect the manufacturer on the spot to see if it has production capacity.

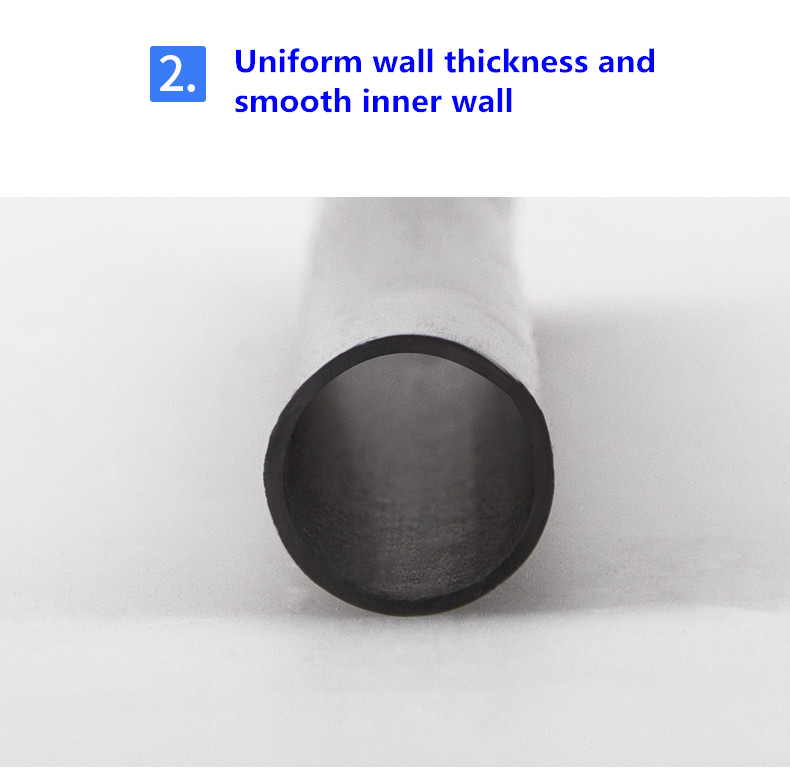

PE plastic pipe for water supply is a replacement for traditional steel pipe and PVC drinking water pipe. The water supply pipe must withstand a certain pressure, usually a PE resin with a large molecular weight and good mechanical properties, such as HDPE resin. The LDPE resin has low tensile strength, poor pressure resistance, poor rigidity, poor dimensional stability during molding, and difficulty in connection, and is not suitable as a material for the water supply pressure pipe. However, due to its high health indicators, PE, especially HDPE resin, has become a common material for the production of drinking water pipes. HDPE resin has a small melt viscosity, good fluidity and easy processing, so the range of its melt index is also wide, and the MI is usually between 0.3 and 3 g/10 min.

Welcome to our company website, thank you for your letter, we will give you a reply in the first time, would you please leave your information and contact way!