Product

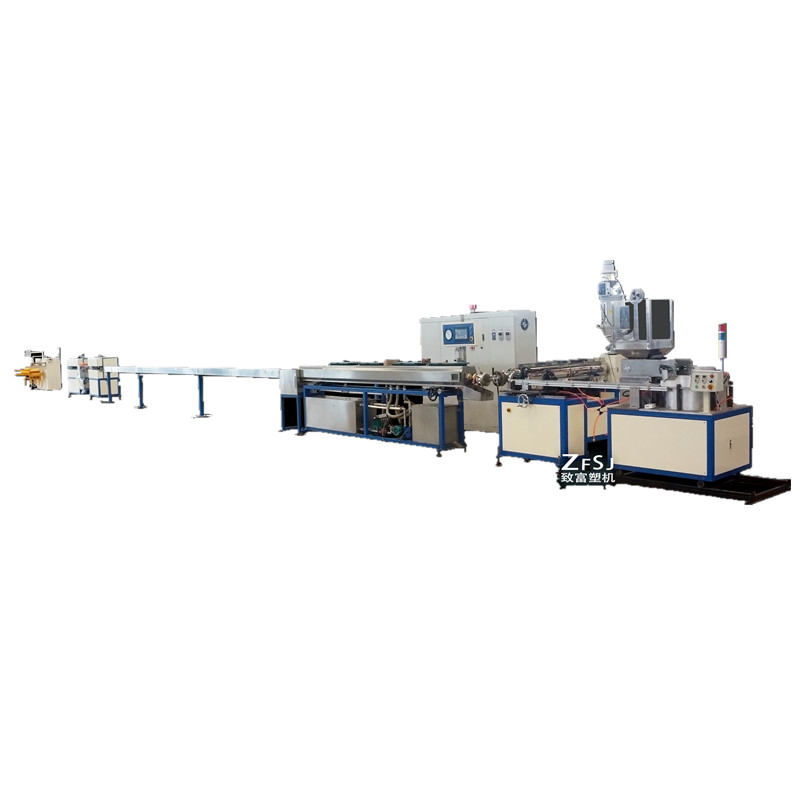

Inline Round Emitter Type Drip Irrigation Pipe Machine is used to produce in-line cylindrical drip irrigation pipe. The cylindrical drip irrigation pipe is widely used in the field of drip irrigation for greening projects such as vegetables, flowers, and afforestation.

Inline Round Emitter Type Drip Irrigation Pipe Machine is used to produce in-line cylindrical drip irrigation pipe. The cylindrical drip irrigation pipe is widely used in the field of drip irrigation for greening projects such as vegetables, flowers, and afforestation.

1. The spacing of the dripper can be adjusted according to the needs of different crops, and can be adjusted equally or not.

2. The dripper adopts the unique design of arc-wide flow channel, full turbulence, self-flushing and strong anti-blocking ability. The laying length can reach 100 meters.

3. It can be used in plains or on hills and slopes.

4. Two or four outlet holes for one dripper, strong anti-blocking ability.

5. Wall thickness up to 1.2 mm and long service life.

1. It adopts computer system control, touch screen operation, stable production process, convenient operation, energy saving and high efficiency.

2. Drip head feeding, screening sorting, conveying inlaying, tapping, punching and winding are completed synchronously with high degree of automation.

3. The extruder screw and barrel are made of 38crmoaia high-quality alloy steel. After ion nitriding, the surface hardness is hv850-1000. The screw is an optimized design of the equidistant unequal-band mixing head, and the extruded material is uniformly plasticized and the surface of the pipe is smooth.

4. The extrusion die and the sizing cooling device are unique in structure, made of special materials, and the sizing size is stable.

5. The tractor adopts frequency conversion speed regulation, which can be applied to various process speed requirements. The track surface has a rubber protective layer to effectively prevent the drip irrigation pipe from being deformed by the traction machine clamp.

6. The punching machine is mechanical punching, which has fast punching speed and stable operation.

7. With double-station coiler, wiring spacing, winding tension, and winding length can be set as needed.

Seedling vegetable beds with drip irrigation system

| Item NO. |

Project |

Technical Parameters SJNX-70-YZ |

| 1 |

Product specification |

φ12mm/φ16mm/φ20mm |

| 2 |

Product wall thickness |

0.5~1.2mm |

| 3 |

Drip spacing |

≥200mm |

| 4 |

Production speed |

50 m/min |

| 5 |

Main drive power |

45KW |

| 6 |

Extrusion amount |

120 kg/h |

| 7 |

Heating power |

30KW |

| 8 | Filter changing way | Durable filter (patent) |

| 9 | Total dripper supply power | 3.06 KW |

| 10 | Dripper supplying speed | ≤180 pcs/min |

| 11 | Tractor driving power | 5.2 KW |

| 12 | Hole drilling way | Mechanical |

| 13 | Hole drilling speed | ≤ 180 pcs/min |

| 14 | Winding driver | 12N.m×2 |

| 15 | Water consumption | 3 m³/h |

| 16 | Air consumption | 1.5 m³/min |

| 17 | Installation power | 100 KW |

| 18 | Overall dimension | 31m×4.5×3m |

Welcome to our company website, thank you for your letter, we will give you a reply in the first time, would you please leave your information and contact way!